Inside Insight

December 20, 2017

BY Lisa Gibson

Advertisement

Advertisement

Related Stories

U.S. fuel ethanol production fell by 3% the week ending April 19, according to data released by the U.S. Energy Information Administration on April 24. Stocks of fuel ethanol were down 1% and exports fell by 23%.

Nebraska Gov. Jim Pillen on April 24 signed a legislative package that includes a tax credit to support the production of SAF within the state. The tax credit applies to eligible SAF that achieves at least a 50% GHG emissions reduction.

A coalition of 36 biofuel producers, ag groups, airlines and other SAF stakeholders on April 24 sent a letter to Agriculture Committee leaders in the House and Senate urging them to provide support for SAF in the upcoming Farm Bill.

Vertimass on April 23 announced that the U.S. EPA has approved registration for blending up to 20% of Vertimass green gasoline with conventional gasoline. This new renewable gasoline product, VertiGas20, is made from renewable ethanol.

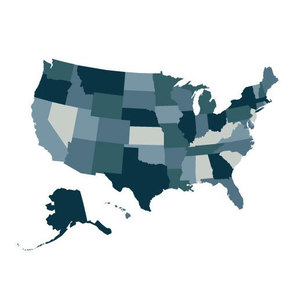

The USDA on April 23 awarded more than $43 million in grants through the Higher Blends Infrastructure Incentive Program to support projects that will increase the availability of domestic biofuels in 15 states.