Shale Play Transforms Natural Gas Economics

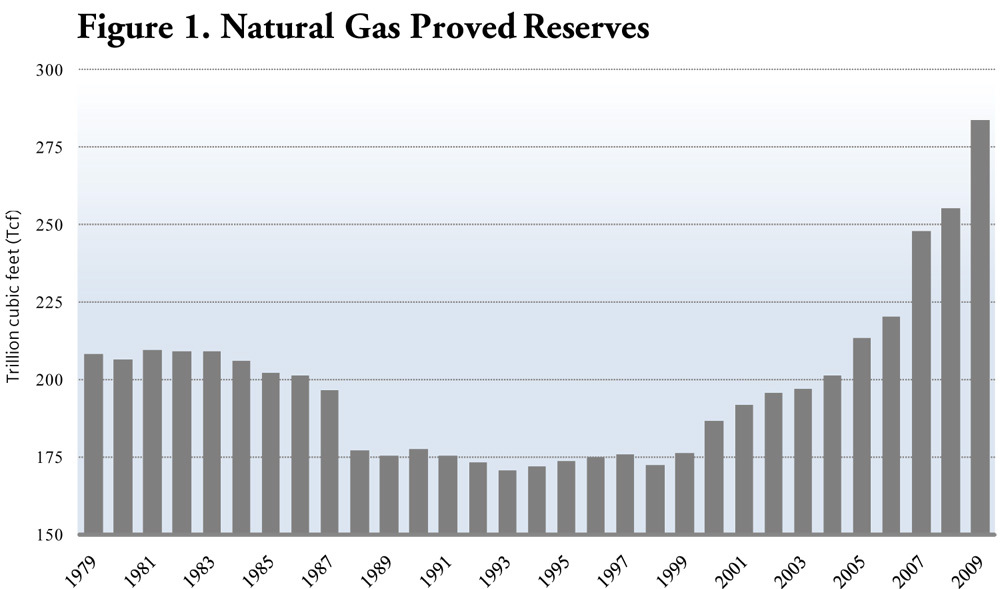

SOURCE: EIA

April 15, 2011

BY Michael Trakhtenberg

Advertisement

Advertisement

Upcoming Events

2024 International Fuel Ethanol Workshop & Expo

June 10-12, 2024

MINNEAPOLIS CONVENTION CENTER | MINNEAPOLIS,MINNESOTA

Now in its 40th year, the FEW provides the ethanol industry with cutting-edge content and unparalleled networking opportunities in a dynamic business-to-business environment. As the largest, longest running ethanol conference in the world, the FEW is renowned for its superb programming—powered by Ethanol Producer Magazine —that maintains a strong focus on commercial-scale ethanol production, new technology, and near-term research and development. The event draws more than 2,000 people from over 31 countries and from nearly every ethanol plant in the United States and Canada.View More

Biodiesel Summit: Sustainable Aviation Fuel & Renewable Diesel

June 10-12, 2024

MINNEAPOLIS CONVENTION CENTER | MINNEAPOLIS,MINNESOTA

The Biodiesel Summit: Sustainable Aviation Fuel & Renewable Diesel is a forum designed for biodiesel and renewable diesel producers to learn about cutting-edge process technologies, new techniques and equipment to optimize existing production, and efficiencies to save money while increasing throughput and fuel quality. View More

Carbon Capture & Storage Summit

June 10-12, 2024

MINNEAPOLIS CONVENTION CENTER | MINNEAPOLIS,MINNESOTA

Capturing and storing carbon dioxide in underground wells has the potential to become the most consequential technological deployment in the history of the broader biofuels industry. Deploying effective carbon capture and storage at biofuels plants will cement ethanol and biodiesel as the lowest carbon liquid fuels commercially available in the marketplace. The Carbon Capture & Storage Summit will offer attendees a comprehensive look at the economics of carbon capture and storage, the infrastructure required to make it possible and the financial and marketplace impacts to participating producers.View More

North American SAF Conference & Expo

September 11-13, 2024

SAINT PAUL RIVERCENTRE | SAINT PAUL,MINNESOTA

Taking place September 11-13, 2024 in Saint Paul, Minnesota, the North American SAF Conference & Expo, produced by SAF Magazine, in collaboration with the Commercial Aviation Alternative Fuels Initiative (CAAFI) will showcase the latest strategies for aviation fuel decarbonization, solutions for key industry challenges, and highlight the current opportunities for airlines, corporations and fuel producers.View More

2025 International Biomass Conference & Expo

March 18-20, 2025

COBB GALLERIA CENTRE | ATLANTA,GEORGIA

Now in its 18th year, the International Biomass Conference & Expo is expected to bring together more than 900 attendees, 160 exhibitors and 65 speakers from more than 25 countries. It is the largest gathering of biomass professionals and academics in the world. The conference provides relevant content and unparalleled networking opportunities in a dynamic business-to-business environment. In addition to abundant networking opportunities, the largest biomass conference in the world is renowned for its outstanding programming—powered by Biomass Magazine–that maintains a strong focus on commercial-scale biomass production, new technology, and near-term research and development. Join us at the International Biomass Conference & Expo as we enter this new and exciting era in biomass energy.View More